Product Info : Hardwood Cuts

Overview

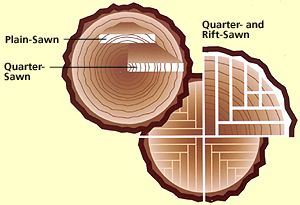

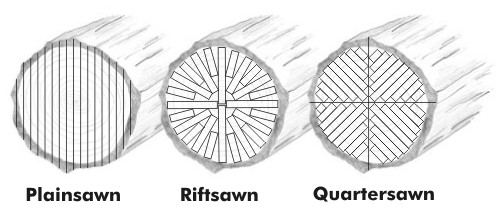

Plainsawn

Plainsawn (or flat-sawn) is where the timber is cut with the grain running across the width of the plank. Plainsawn wood highlights the grain, loops and growth swirls of the wood. This method is the most economical because it produces the widest boards with very little waste - approximately 80% of hardwood is milled this way. Plainsawn lumber will tend to expand and contract more across the width of the board due to the flat-grain patterns. Click here to see an example of the pronounced grain patterns.

Quartersawn

Quartersawn lumber is produced by first quartering the log and then sawing perpendicular to the growth rings (60 to 90 degrees). This process produces relatively narrow boards with vertical grains. The vertical grains make Quartersawn hardwood more stable than Plainsawn hardwoods but the process isn’t as efficient and produces more waste making Quartersawn hardwood more expensive to produce.

Riftsawn

Riftsawn lumber is very similar to Quartersawn lumber and has many of the same benefits but the wood is cut at a slightly different angle (30 to 60 degrees) that accentuates the vertical grain and minimizes the flake effect that is common in Quartersawn lumber. Riftsawn timber generally has a very consistent vertical grain pattern throughout each plank. Unfortunately this process produces a lot of waste and the low yield has made Riftsawn lumber a rarity at the lumber yard.

Rift and Quartered